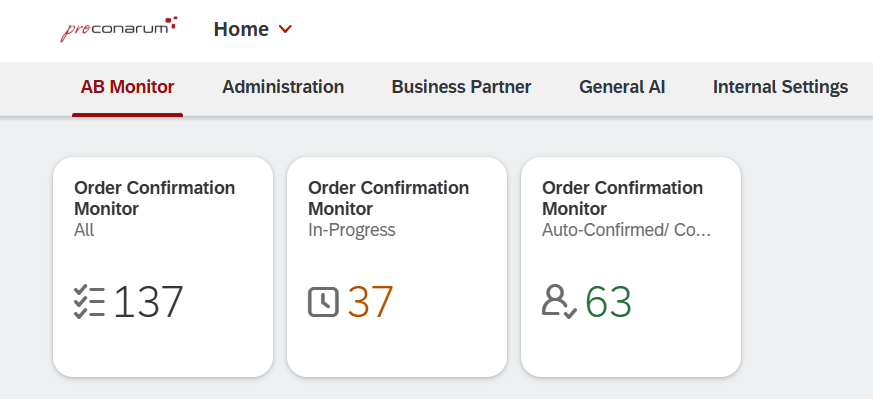

¶ 1. Dashboard Overview

¶ Workzone navigator

To access the app:

1. Go to your SAP BTP Work zone URL

2. Navigate to your workspace: Purchasing Management

3. Click on the AB Monitor tile

in AB Monitor tile, we can find a quick update for number of supplier confirmations with status: auto-confirmed (without deviation/within tolerances), Open, In processing.

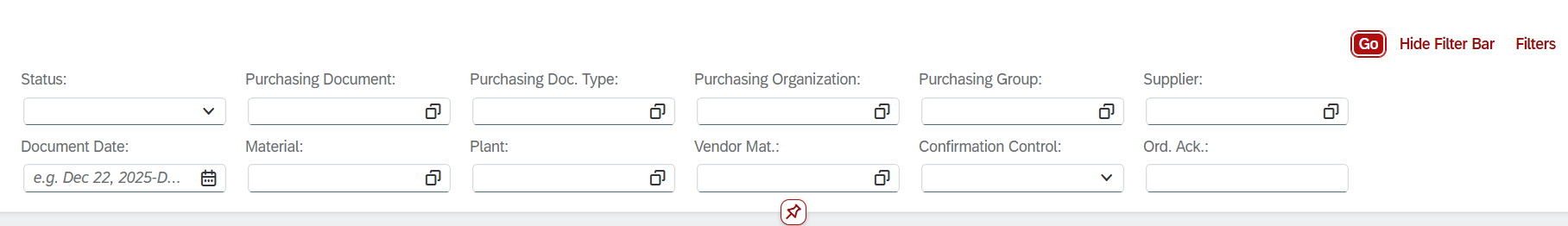

¶ Filter Options:

- Status: drop-down list for status of confirmation record

- Purchasing Document

- Purchasing Document Type

- Purchasing Organization

- Purchasing Group

- Supplier

- Document Date

- Material

- Plant

- Supplier Material

- Confirmation Control

- Order Acknowledgement

User can hide or display Filter Bar and customize the filter list with the option “Hide Filter Bar”, “Filters”

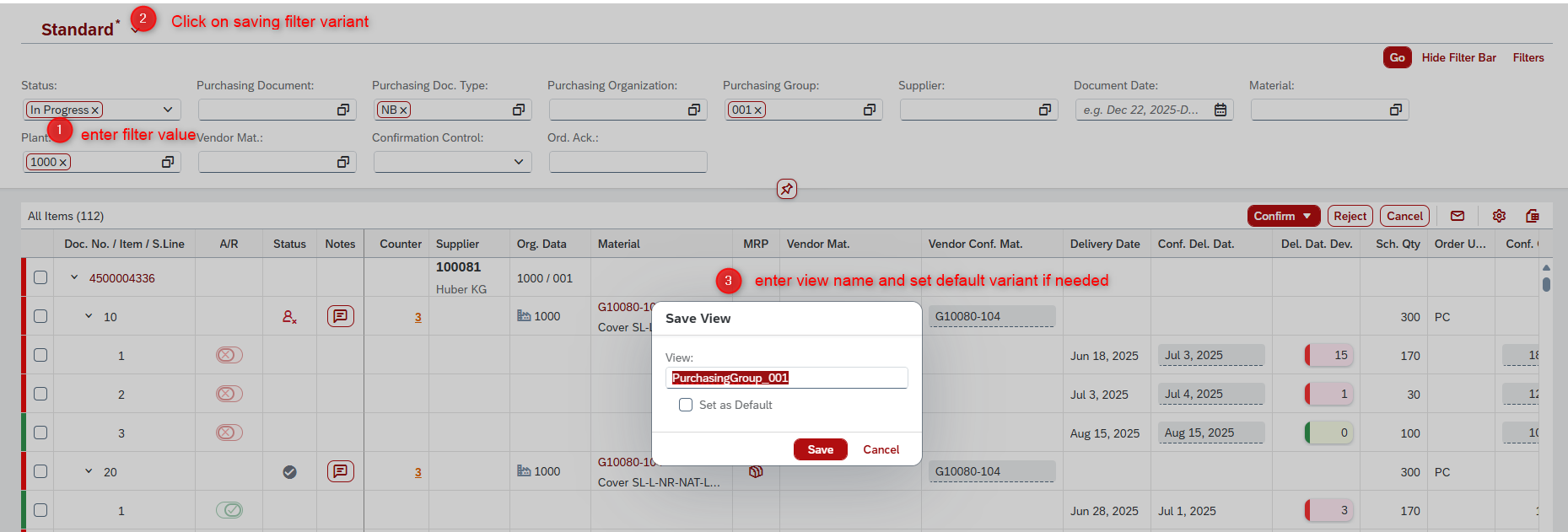

User can save his own filter variant for future use by saving filter variant

¶ Worklist

This worklist screen shows purchase order in 3 levels (purchase order header, items, schedule lines) and their confirmation details, highlighting discrepancies (deviations) between the ordered and confirmed delivery data.

In toolbars, user can do following actions with the worklist

- Export the data to excel file

- Change layout setting of columns shown in screen

Structure of the Worklist Table

Each row corresponds to a specific purchase order, and the rows are organized hierarchically by:

- Document number (Doc. No.)

- Item number

- Schedule line number (Item / S.Line)

Example:

4500004138 / 10 / 1 is one schedule line item of Purchase Order 4500004138.

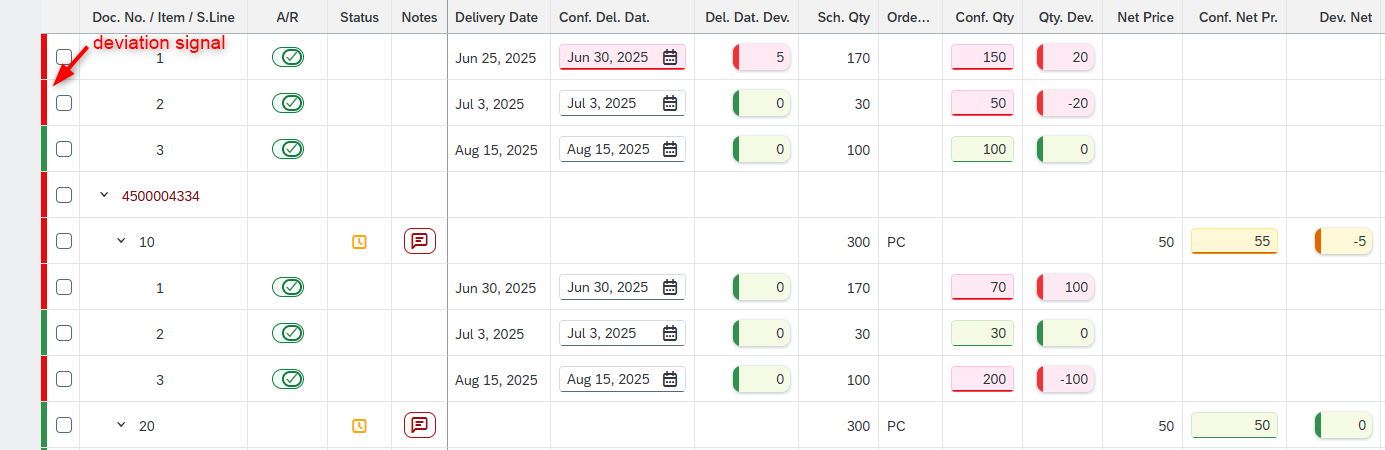

¶ 2. Working with Deviations

¶ 2.1. View AB confirmation details

Column Explanations

| Column | Description |

|---|---|

| Deviation | Red: indicates a mismatch in either delivery date, confirmed quantity, confirmed price or vendor material number Green: indicates that there is no deviation or deviation in tolerances |

| Doc. No. / Item / S.Line | Shows the Purchase Order (PO) number, line item, and schedule line. Expandable tree view. User can navigate to view purchase document by clicking on hyperlink in Purchase Order number |

| A/R (Accept/Reject) | Indicates whether a schedule line is accepted or rejected. All schedule lines are set as accepted by default |

| Counter | Shows number of supplier confirmation received for each purchase order items User can view Confirmation history log by clicking on the hyperlink in Counter number |

| Organizational data | Including Purchasing Org/ Purchasing Group and Plant (in item level) |

| Supllier | Supplier number with supplier name |

| Material | Ordered material number - with material description |

| MRP | Link to Stock/Requirements List if MRP exists for selected material |

| Vendor material number | Ordered vendor material number |

| Confirmed vendor material number | Confirmed vendor material number (highlighted as red if confirmed material numbers is different from ordered vendor material number) |

| Delivery date | Originally planned delivery date from the purchase order (PO). |

| Confirmed delivery date | Confirmed delivery date for each schedule line item (highlighted as red if confirmed is different from ordered scheduled date) by supplier in order confirmation |

| Delivery date deviation | The deviation (in days) between the confirmed delivery date and the original delivery date. A negative number means delay. |

| Scheduled Quantity | Scheduled quantity from the PO — the quantity that was ordered. |

| Order Unit | The unit of measure for the order (e.g., PCE = pieces). |

| Confirmed quantity | The quantity confirmed by the supplier. |

| Quantity deviation | Difference between the scheduled quantity and the confirmed quantity (highlighted as red if any difference) |

| Net Price | The agreed net price per unit in the PO. |

| Confirmed net price | The price confirmed by the supplier. |

| Deviation net price | The deviation between the confirmed net price and the PO net price. |

| Order acknowledgment number | Confirmation number |

| Comment | Comment input by user |

| Incoterm & Incoterm 2 | from PO data |

| Terms of payment | from PO data |

| Date received | Date/ time when inbound ORDRSP Idoc received for supplier confirmation |

| MRP | Button to navigation to MRP if existing |

| PIR | Button to navigation to purchasing info record if existing |

Expand a purchase order hierarchy to view PO items and schedule lines data and comparisons:

- Confirmed vs. ordered vendor material number

- Confirmed vs. Ordered Quantity

- Confirmed vs. Requested Delivery Date

- Confirmed vs. PO item Price

Visual Cues

- Red line in "Deviation" indicate a mismatch in either delivery date, confirmed quantity, confirmed price or vendor material number.

- Deviation symbol in Purchase Order header level is red if one of items contains deviation

- Deviation symbol in Purchase Order item level is red if one of schedule lines contains deviation

- Red-highlighted fields (e.g., Conf. Qty) signal mismatches or missing values needing attention.

- Orange-highlighted fields (e.g., Conf. Qty) signal mismatch values but within tolerance.

- Green-highlighted fields (e.g., Conf. Qty) means no deviation.

- Negative values (e.g., in "Del. Date Dev.") indicate late deliveries compared to the planned date.

¶ 2.2. Taking Action

¶ 2.2.1. Auto-Confirm

This is an automatic process triggered by the system when there are no deviations/ or deviation in tolerances between the PO and the incoming IDoc (supplier confirmation) data.

- Use Case: If the confirmation exactly matches the PO data (dates, quantities, etc.) or deviation exists but in tolerances

- System Behavior:

- Automatically posts the confirmation.

- Sets the status to

AUTO_CONFIRMED.

¶ 2.2.2. Confirm

This is a manual action where the user reviews deviations (delivery date, quantity, price, etc.) and confirms supplier responses.

- Scope: Can be done at item or header (entire PO) level.

- Actions:

- User can change confirmed delivery date, quantity, and unit if needed.

- User must select at least one item and toggle “Approve” in the schedule line.

- A comment is optional.

- System Behavior:

- If purchase order confirmation (POC) is created successful, the confirmation status is set to

CONFIRMED. - The user sees a success message or, in case of issues, warning popups to take corrective actions before posting the POC.

- If purchase order confirmation (POC) is created successful, the confirmation status is set to

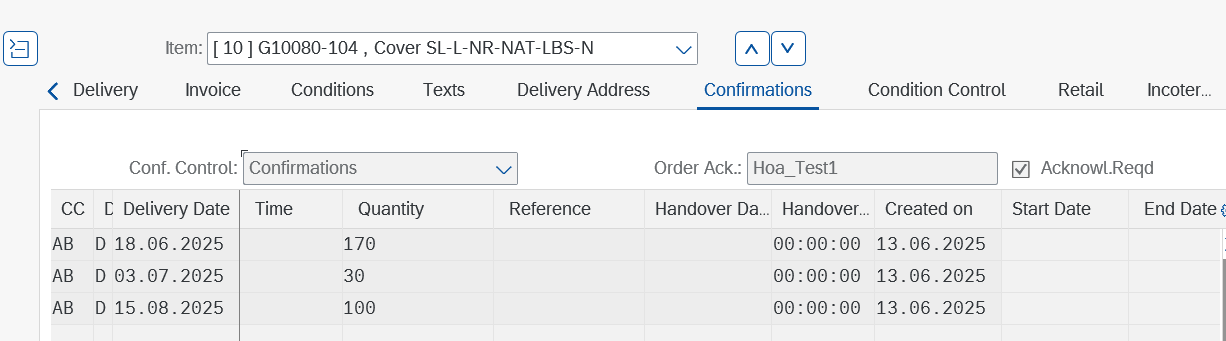

¶ 2.2.3. Confirm & Update

User can choose this option to post POC and update PO data according to supplier confirmation.

- Scope: Can be done at item or header (entire PO) level.

- Actions:

- User can change confirmed delivery date, quantity, and unit if needed.

- User must select at least one item and toggle “Approve” in the schedule line.

- A comment is optional.

- System Behavior:

- Schedule Line: Confirmed delivery date and quantity are updated at schedule line level.

- Item Level:

- Quantity and delivery date are updated based on the earliest confirmed schedule line.

- Comment will be added to Item text

- New condition record type EDI1, EDI2 are created to show the adjusted price. Gross price will not be updated.

- Confirmation Tab: A new record is created (with confirmed schedule lines). If records exist, data will be overwritten.

¶ 2.2.4. Reject

This is a manual action where the user reviews deviations (delivery date, quantity, price, etc.) and reject supplier responses.

- Scope: Can be done at item or header (entire PO) level.

- Actions:

- User must select at least one item and toggle “Reject” in the schedule line.

- If no PO or item is chosen, prompt users to select at least one line.

- When user rejects PO header/ items, all relevant schedule lines will be rejected as well

- A comment is mandatory for users to enter comment upon rejecting.

- System Behavior:

- Mark the rejection indicator in the confirmation tab with "X."

- The PO item will be marked as “deleted” upon confirmation rejection.

- If purchase order confirmation (POC) is rejected, the confirmation status is set to

REJECTED.

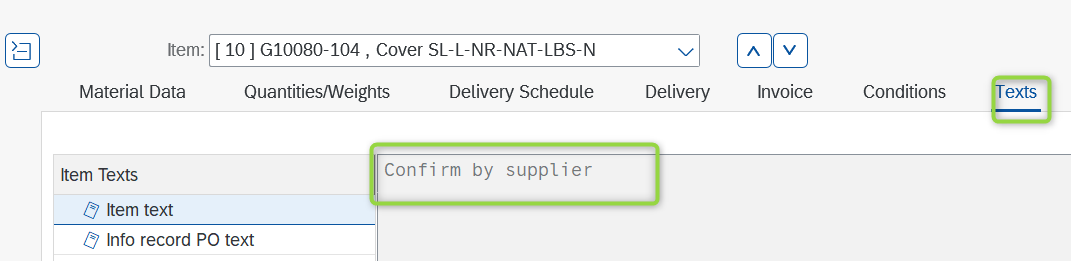

¶ 2.2.5. Reject by supplier

This is an automatic process triggered by the system when supplier rejects the PO.

- System Behavior:

- Automatically reject the confirmation.

- Sets the status to

AUTO_REJECTED.

¶ 2.2.6. Cancel

Users review deviations and cancel records, either the entire PO or specific items. E.g., when IDoc is duplicated.

- Scope: Can be done at item or header (entire PO) level.

- Actions:

- User must select at least one item and press Cancel button.

- If no PO or item is chosen, prompt users to select at least one line.

- System Behavior:

- When user cancel PO header/ items, the confirmation status is set to

CANCELLED - No changes are made to PO item data upon cancellation

- When user cancel PO header/ items, the confirmation status is set to

¶ 2.3. Mass Processing

AB Monitor allows users to perform multiple actions—confirm, confirm and update, reject, or cancel—on multiple selected purchase orders/ purchase order items simultaneously.

- Action: Users select the list of POs/ PO items and choose the desired mass processing operation—Confirm, Confirm & Update, Reject, or Cancel.

- Processing:

- The system processes all selected records according to the chosen action.

- For "Confirm & Update," relevant POC and PO are updated automatically.

- For "Reject," users may be prompted to add comments or reasons.

- Notification & Status Update:

- The system provides a summary or notification indicating the success or failure of each item.

- Record statuses are updated accordingly (e.g., Confirmed, Rejected, Cancelled).

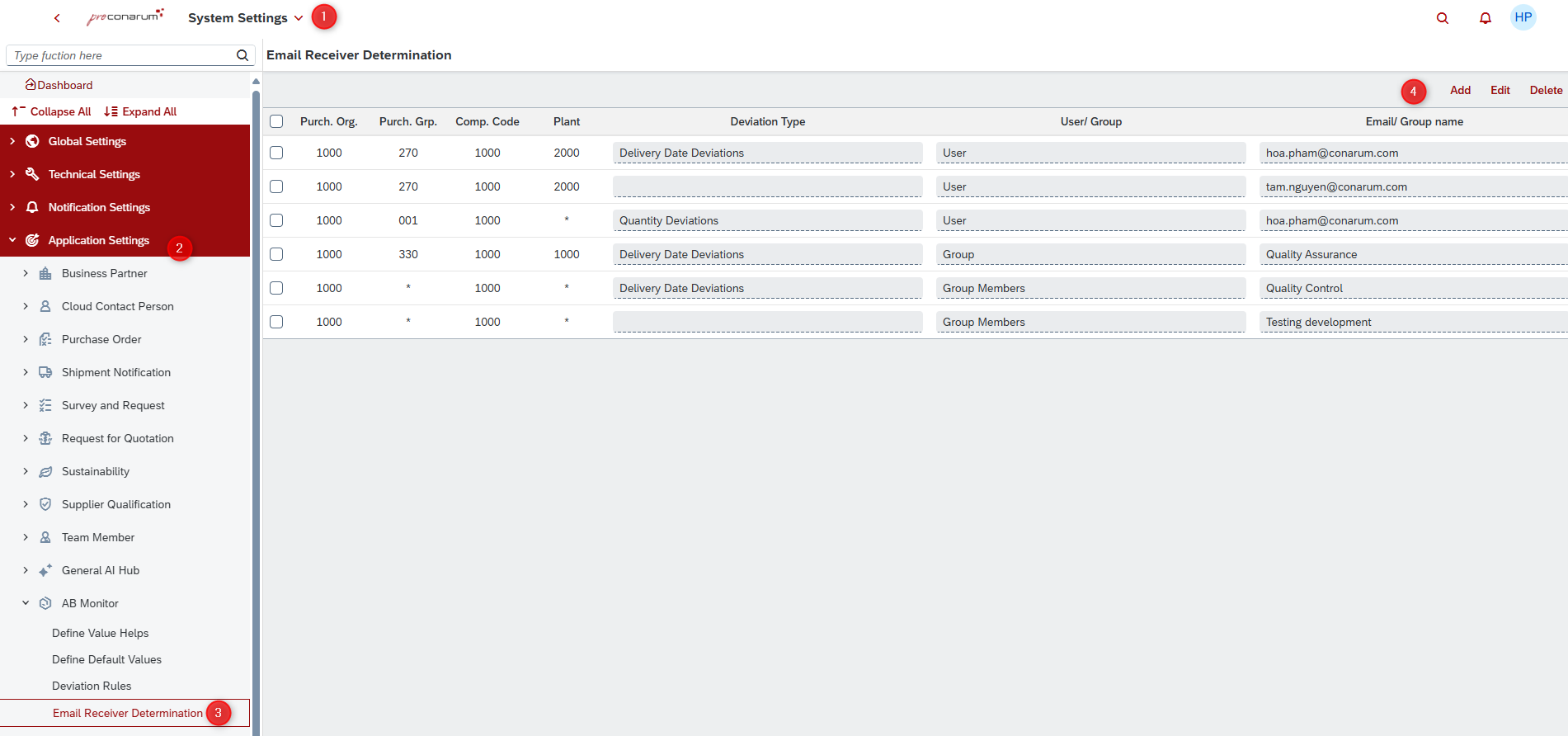

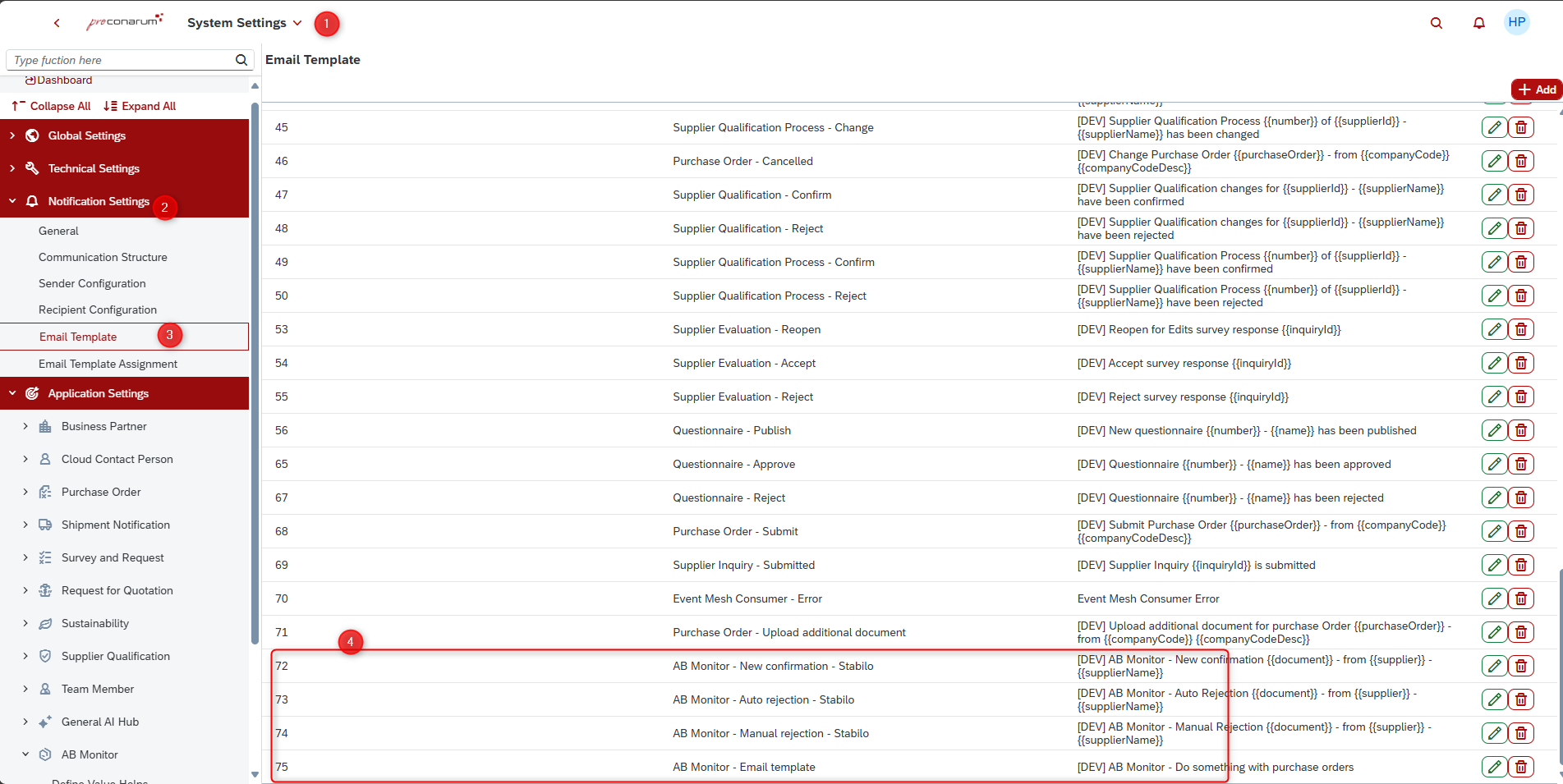

¶ 3. Notifications & Alerts

To proactively alert designated personnel when deviations are detected in supplier PO confirmations, ensuring timely action and resolution, AB Monitor includes an automated email notification functionality.

- Notification Triggers:

- The system triggers email notifications in following cases

- a deviation is detected.

- supplier rejects purchase order

- AB Monitor user rejects the confirmation

- Notifications are sent separately based on deviation type:

- Quantity or Delivery Time Deviations: Sent to the dispatcher or warehouse employee.

- Price Deviations: Sent to the buyer responsible for processing.

- The system triggers email notifications in following cases

- Recipient Management:

- Email recipients are maintained in the system's admin settings.

- The admin can configure and update email groups or individual addresses for each deviation category.

- Customization & Flexibility:

- Admin can customize email templates and define recipients.

- Flexibility to add or modify recipient groups as needed.

Additionally, users can send emails directly from the AB Monitor screen by selecting single or multiple PO/ PO items for email notifications or reminders.

- Process:

- The system opens an Outlook email compose window.

- It automatically populates the email with necessary PO data and any detected deviations (such as deviations in PO data).

- User Action:

- Users can freely add their own email content.

- They can also select or specify email recipients within the compose window.

This functionality allows flexibility for users to manually initiate email communication related to PO deviations directly from the system, leveraging Outlook integration for convenience.

¶ 4. Navigation Links

These links enable efficient navigation within the system, connecting related data such as purchase orders, materials, and confirmation logs for quick reference and process management. It also streamline access to related purchase data and planning details, facilitating efficient management and referencing within procurement processes.

- Link to Purchase Order

- Function: Provides access to the specific purchase order.

- Description: A hyperlink is attached to the PO number, allowing quick navigation to the detailed PO.

- Link to Material

- Function: Allows navigation to material details.

- Description: A hyperlink attached to the material number for direct access to material-related information.

- Link to Confirmation Log

- Function: Opens the confirmation counter log.

- Description: A hyperlink attached to the confirmation log, showing only the relevant confirmation entries for the selected PO item.

- Link to Purchase Info Record

- Function: When a user selects a line item and clicks on the Purchase Info Record,

- Description: It navigates to the purchase info record app for detailed information related to the selected entry.

- Link to MRP

- Function: User chooses a PO item with a specific Material number and clicks on the MRP button.

- Description: It navigates to the MD04 app for Material Requirements Planning (MRP), enabling detailed planning information for the selected material.